Hardness (Shore A/D)

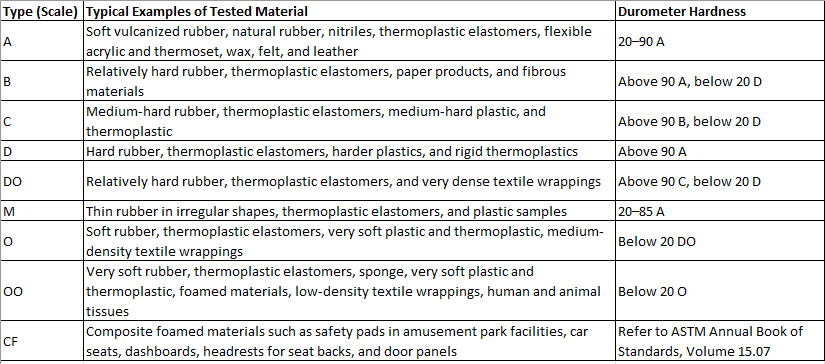

The hardness (Shore A/D) of a material is a measure of its resistance to permanent indentation. The device used to test rubber materials is called a Durometer. There are twelve scales for defining the hardness of different materials: A, B, C, D, DO, E, M, O, OO, OOO, OOO-S, and R. The different scales apply to materials with different characteristics; for example, scale A is suitable for soft plastics. The scale values range from 0 to 100, with 100 durometer indicating the hardest material. The standard durometer testing device was developed by Albert Ferdinand Shore, and results from this device are referred to as Shore hardness.

Importance:

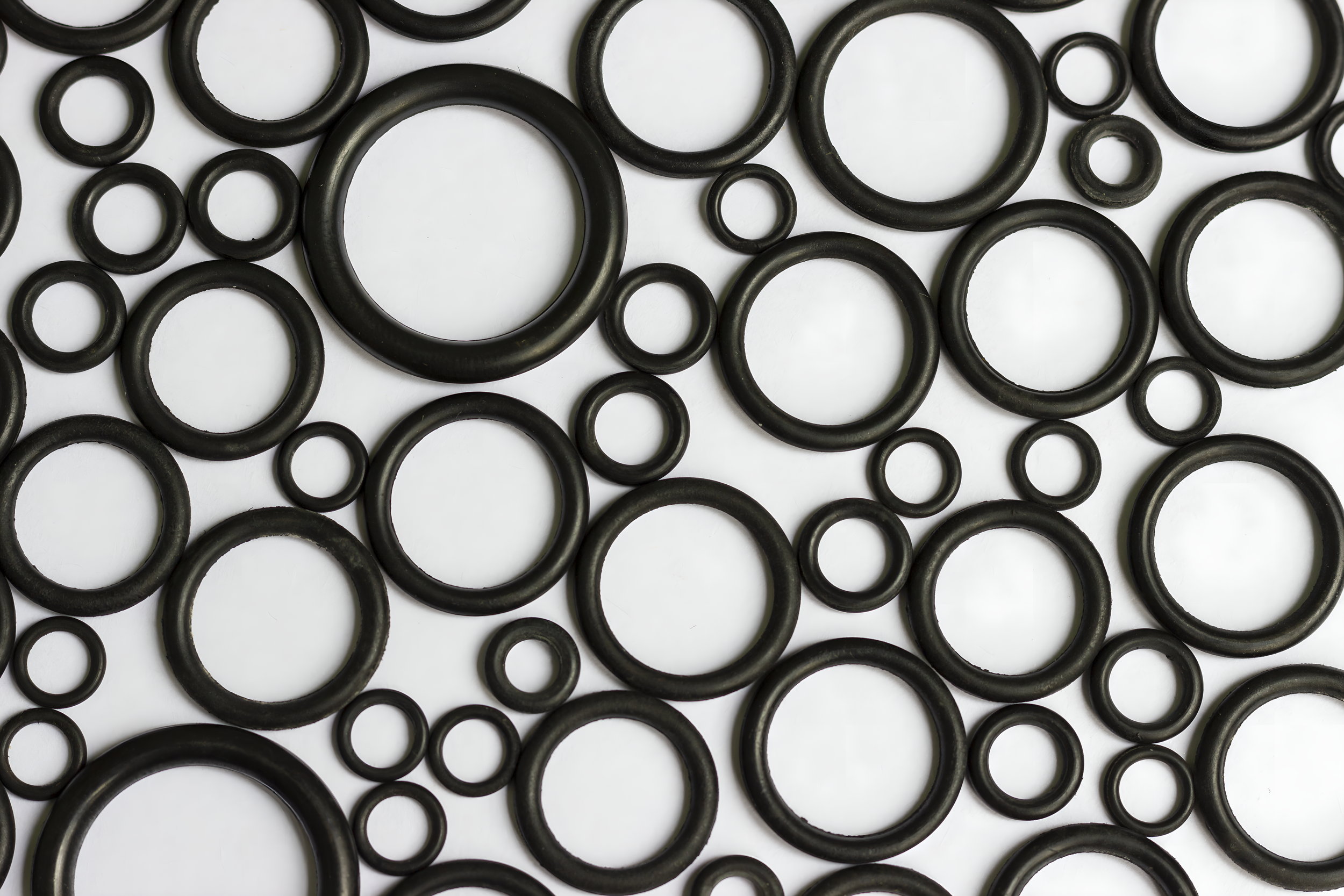

Shore hardness becomes an important factor in determining the appropriate type of rubber for use under pressure. Thus, the correct hardness must be chosen based on the expected pressure in the system.

Measuring Hardness:

A durometer measures the depth of an indentation made in a material by a given force applied through a standard test foot. This depth depends on the hardness of the material, its viscoelastic properties, the shape of the test foot, and the duration of the test. Durometers according to ASTM D2240 allow for the measurement of initial hardness, or the hardness of the indentation after a given time period. The basic test involves applying a consistent force, without impact, and measuring the hardness (depth of the indentation). If a time-related hardness measurement is required, a force is applied for the necessary duration before the measurement is taken.

The hardness (ASTM D2240) of a material is determined according to one of the twelve durometer scales. The testing method is based on the penetration of a specific object that causes an indentation when a force is applied to insert this object into the material under certain conditions. The indentation hardness is inversely related to penetration and depends on the material's elasticity modulus and viscoelastic properties. The geometry of the penetrating object and the applied force affect the measurements, so there is no simple relationship between measurements obtained with different types of durometers or other tools used to measure hardness. This testing method is empirical and intended primarily for control purposes. The indentation hardness measured is not related to any fundamental property of the material being tested.

Shore Hardness ASTM D2240 and Elastic Modulus:

Several attempts have been made to correlate ASTM D2240 with the elastic modulus. Below is an example of such an attempt:

When SA is the hardness ASTM D2240 type A, SD is the hardness ASTM D2240 type D, and E is Young's modulus in MPa.